Tiger Machine

Based in Japan, TIGER Machine has been developing and manufacturing innovative machinery since 1950. Their dedication to research and the latest technology allows them to create new and improved products that Pathfinder Systems can offer to the US and Canadian markets through our exclusive partnership.

Tiger Equipment

Concrete Production

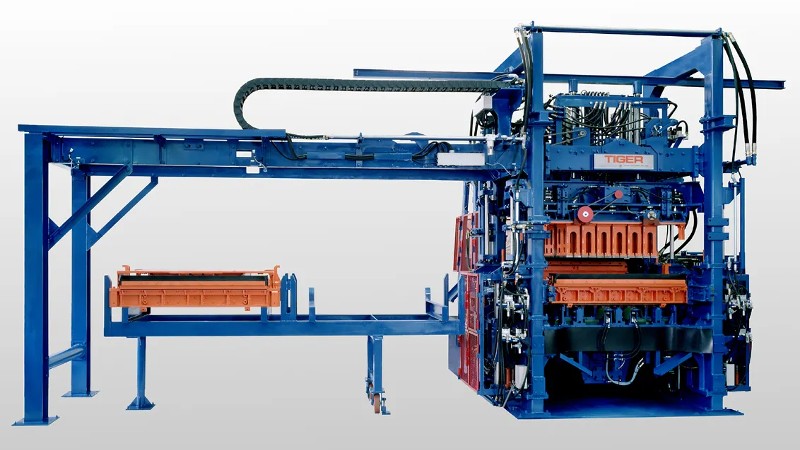

Model S

TIGER Machine

Built to last and compatible with many existing foundations, the Model S features fast mold and height changes, along with highly adjustable and user-friendly controls.

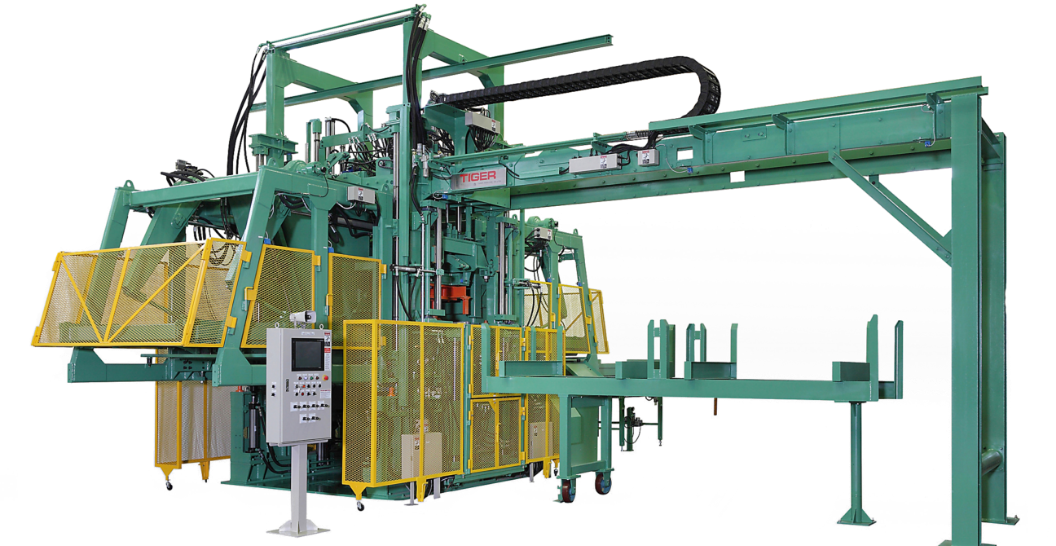

PS Series

TIGER Machine

The industry’s first fully automatic mold change system, capable of running new products and most competitor molds.

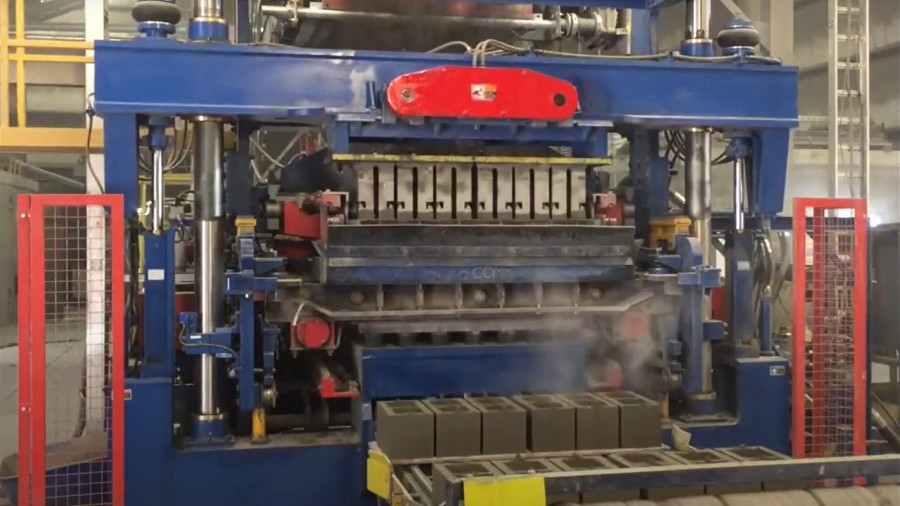

TG Series

TIGER Machine

TIGER’s largest, fastest and most sophisticated machines for the production of high-quality concrete masonry units, with product mold changes in under five minutes.

Block & Paver Handling Systems

Pallet Transporter System

TIGER Machine

Customizable pallet transport system capable of keeping up with the pace of other high-volume concrete products machines.

Robotic Pallet Accumulator

TIGER Machine

A highly advanced design based on traditional pallet transport equipment. This is an economical, efficient, and flexible system that not only transports production pallets from the wet side, to the curing kilns, and to the dry side, but also keeps up with the pace of other high volume concrete production machines.

Rack Transfer System

TIGER Machine

The TIGER RTS’ first in first out pallet handling provides consistent and quality concrete products.

Cubing & Splitting Solutions

CC Cuber

TIGER Machine

Cube two different products at the same time with a completely in-line system that’s compatible with specialty lines.

CP Cuber

TIGER Machine

Each segment of this cuber uses segmented tier clamps featuring their own hydraulic cylinders.

TSP Splitter

TIGER Machine

Full multi-purpose units with the most advanced features and the best value in the industry.

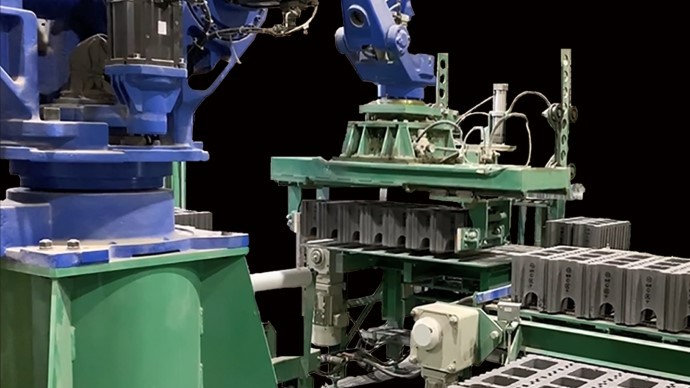

Robotic Cuber

TIGER Machine

Able to make three rows of architectural blocks, this system can cross stack standard or corner cubes on wood or plastic pallets.

Wet Cast

TIGER’s complete wet cast line is designed to handle a full range of retaining products and accommodate pavers, slabs and flagstones. The modular system can be assembled to meet your specific requirements with the option to start with a basic system and expand when needed. Pathfinder provides the material handling, color blending and mixing system to match the production requirements for a full-system solution.

Indexing Conveyors

TIGER Machine

Automatically indexes molds through an atmospherically-controlled curing chamber.

Dosing System

TIGER Machine

Control the specific volume of material being fed to the mold in multiple cavities. Ideal for smaller retaining walls, veneer units and pavements.

De-Molder

TIGER Machine

TIGER offers solutions for de-molding wetcast product from traditional wetcast poly or steel molds. This can include but is not limited to product flippers, vacuums and robotic demolding.

Roller Screed

TIGER Machine

Automatically assists with cleaning of wetcast molds post dosing. This reduces labor requirements to ensure a beautiful product after curing and reduces mold clean-up prior to re-poring a mold.

Vibrating Table

TIGER Machine

The TIGER vibration table is composed of a roller screed, hopper with rubber hose, and an indexing conveyor.

Stacker/Destacker

TIGER Machine

Stacks and de-stacks certain types of wetcast molds for storage. The de-stacker allows a forklift operator to place multiple molds on your production line, and the machine will de-stack and index individual molds to your first production station.

About Tiger

TIGER Machine has now been developing and manufacturing innovative concrete production machinery to meet the needs of customers for over 70 years. TIGER supplies over 50% of machinery to the Japanese market for the production of concrete products such as concrete masonry units, concrete pavers, retaining wall and concrete architectural products. Since 1998, our partnership has also made TIGER equipment available in the US and Canadian markets.