Facility Development

Pathfinder Systems provides full-facility development consulting and management services for your plant launch. Our experienced team of professionals

Facility Development Process

Your Path to Concrete Dominance Starts with Pathfinder

We cover more than just custom concrete block and paver equipment packages, Pathfinder can build you a state-of-the-art block or paver plant from the ground up. We provide everything you need for your concrete plant including batching, production, curing and secondary processing options. We can also offer additional features like packaging.

Building a complete concrete production plant with Pathfinder Systems involves leveraging advanced technology and comprehensive services to create an efficient, state-of-the-art facility. We specialize in the design and implementation of turnkey concrete production solutions, integrating robust machinery and automation systems to streamline operations. Our expertise covers the full spectrum of plant construction, from initial site evaluation and customized design to equipment installation and operator training. Utilizing our solutions ensures that your plant meets high standards of quality and productivity, with features such as automated batching, precise material handling, and efficient curing processes. This holistic approach not only enhances production capacity but also optimizes energy consumption and reduces operational costs, ultimately delivering a highly effective and sustainable concrete manufacturing environment.

We will work with you to design, purchase, construct and commission your concrete manufacturing plant from greenfield to completion in eight to twelve months.

1. Consultation

Creating a complete concrete plant with Pathfinder begins with conceptualizing your vision during an initial consultation meeting. This includes finding the ideal site location, designing and planning the layout of the space, selecting the right product lines to meet customer needs, and ensuring that all building, product and performance specifications are met.

2. Quote

We’ll prepare a quote including all of the pricing, terms and conditions in one document and send it to you for your review and approval before moving forward with the next step. Service technicians will be assigned to your new facility once the quote has been approved.

3. Timeline

After approval of your proposal, we’ll work to develop the project timeline with you. The timeline will include all stages of your build; from constructing the facility, to equipment installation, to our extensive equipment testing.

4. Installation

The service technicians assigned to your plant will coordinate the installation of your equipment and supervise the process of building the new plant over the 8 to 12 month period.

5. Testing

Once the plant has been completed, your service technicians will stay on site for equipment testing to ensure that your new concrete plant is fully functional and running as smoothly as possible. They can also provide follow ups for refining operations or training needs.

CLIENT STORY

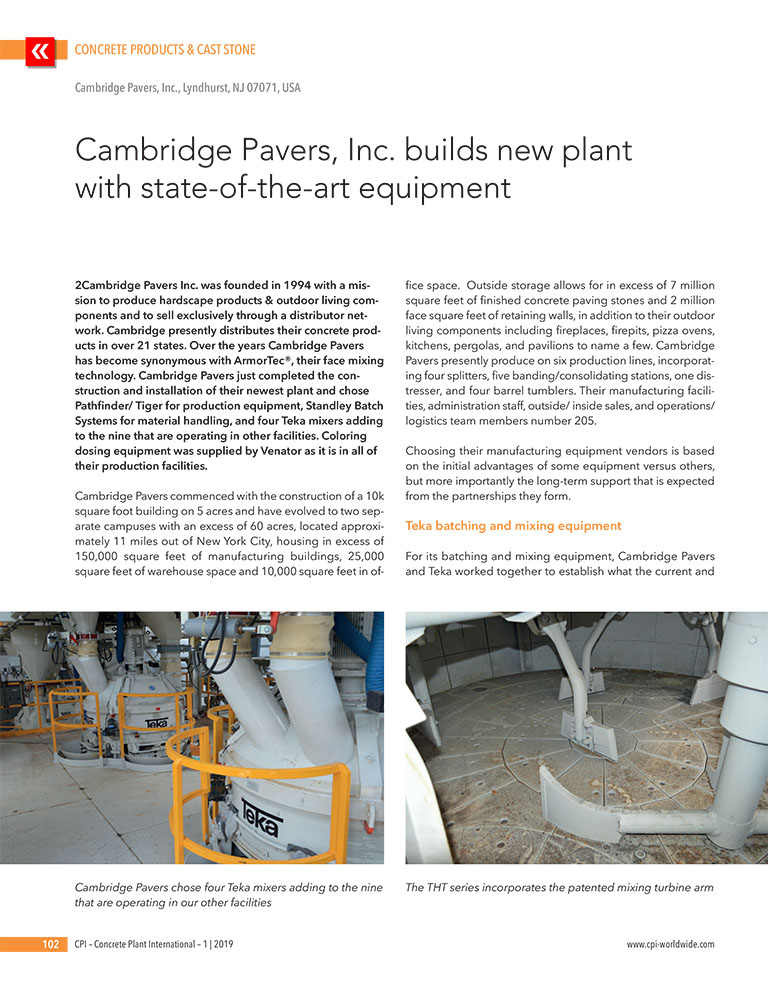

Cambridge Pavers, Inc. Builds New Plant with State-of-the-Art Equipment

Cambridge Pavers, Inc. | Lyndhurst, NJ, U.S.

Featured Service: Facility Development – TIGER, MERTs, CureTec

When they needed production equipment for their new 150,000 square foot plant, Cambridge chose Pathfinder Systems not only for their product quality, but for their quality long-term support and partnerships.