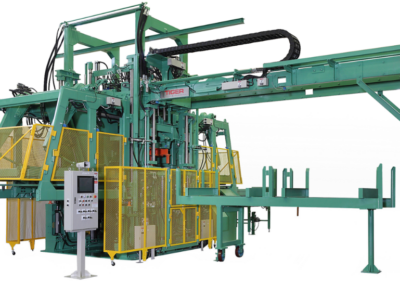

TIGER PS Series

The Industry’s First Fully-Automatic Mold Change System

Equipment Concrete ProductionPS Series Features

Automatic Mold Change

High Capacity

Hassle-Free Sensors

Production Tracking & Maintenance

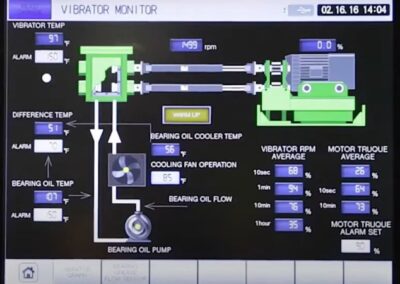

Predictive Maintenance Sensors

Full Cycle Customization

Tiger PS-1000HD

The TIGER PS-1000HD has the ability to control cycles based on position or time. It has intuitive controls coupled with an intelligently designed graphic interface, making operations and adjustments instinctual. The intelligent feed drawer adjusts on compaction time, while the self-monitored bearing temperatures and auto grease system help to ensure proper operating parameters on the vibration table.

We also offer compatible steel pallets.

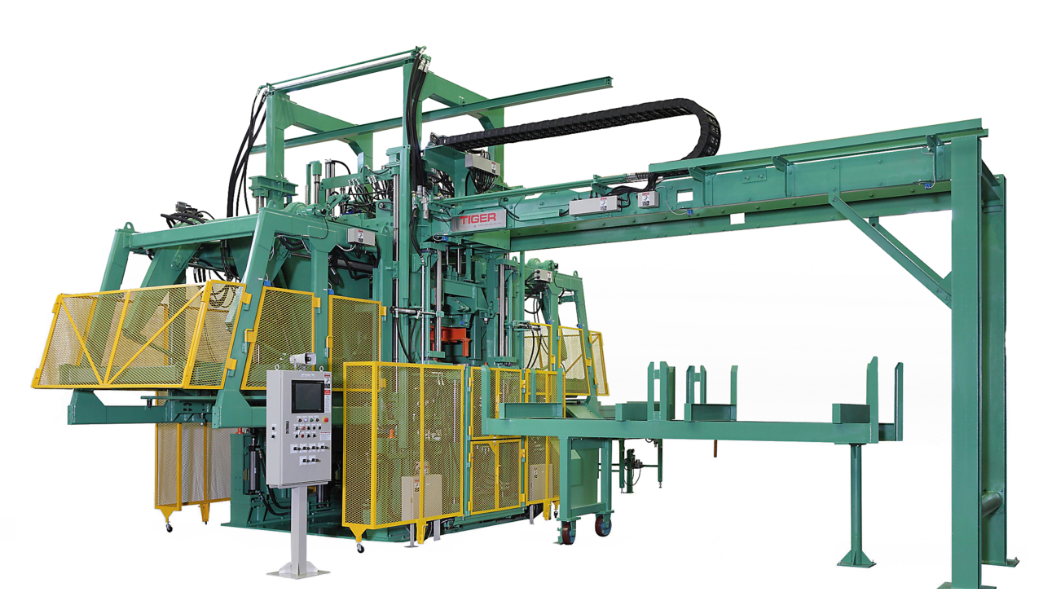

TIGER PS-1400

The TIGER PS-1400 creates crisp monolithic product with the help of a large pallet and an advanced table vibration system. Utilitizing run fine-tuning for precision, speed and efficiency the PS-1400 delivers exceptional product even in low height. It is adaptable to many mold brands and a large pallet delivers more product in less time.

Details

- Takes less than five minutes using the same agitator and cut off bar, 10 minutes if changing the agitator grid and cut off bar

- Push button height change

- Capable of making products from 30mm to 300 mm

- Ability to run most competitors’ molds

- Ability to run new products

- Engineered and built for heavy-duty, continuous use

- Does not require expensive pits or foundations

Resources

Related Equipment

Molds & Mold Parts

Standard Batch Plants

De-Cumulative Batch Plants