EZ Modular Batch Plants

Equipment Ready Mix Batch PlantsEZ Modular Plant Features

Customizable

Heavy-Duty

Durable

Quick & ‘EZ’ Set Up

EZ Modular Batch Plants are completely customizable and meet the highest engineering standards. The modular plants come in the standard model for companies looking to produce 150 yards of concrete per hour, or the Big EZ model for those who need a larger framework and faster production time.

Plants Details

Aggregate

- 170 tons, heaped capacity aggregate storage

- 3-4 compartments

- 550 cubic ft. aggregate batcher with 60,000 lb. scales

- Two-inch piston vibrator mounted on aggregate batcher

- 30″x 41′ conveyor with 15 HP TEFC motor

Cement

- Two 622/518 bbl. (2488 cubic ft.) cement silos

- Ladder with safety cage to top of silos

- Handrails around top of silos

- 120 cubic ft. cement batcher with 12,000 lb. scales

- 12″x12′ screw conveyor

Water

- Three-inch water meter with piping to grade

Pre-Wiring

- 200 Amp 460 volt main service

- 30 Amp 110V service pre-wiring

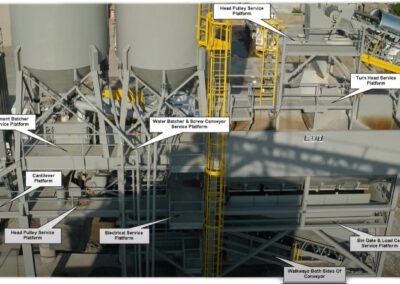

Maintenance Platforms

- Walkways on both sides of conveyor and bin gates

- Service platforms at conveyor head section, cement batcher discharge, silo gates and screw conveyor

Optional Features

- 480 gallon water-holding hopper with three-inch butterfly float controlled

- Inlet valve and six-inch butterfly discharge valve

- 480 gallon water batcher suspended on load cells with six-inch butterfly valve discharge valve

- 36″x41′ conveyor with 30 HP TEFC motor

Optional Silos

- 745/621 bbl.

- 971/809 bbl.

- 1198/998 bbl.

- 14″x12′ screw conveyor

- Central dust collection with internal ductwork

- Cantilevered platform for central dust collector

- Filter vents for silos and cement batchers

- Low pressure air system for silo aeration